Revolutionizing Industries with 3D Printed Wings: Unlocking New Possibilities in Business and Engineering

In the rapidly evolving landscape of modern technology, 3D printed wings stand out as a remarkable innovation that is transforming how businesses approach design, manufacturing, and development. From aerospace ventures to fashion industry adaptations, the advent of 3D printed wings symbolizes a new era of creative freedom, efficiency, and sustainability. Understanding the profound impact of this technology is essential for entrepreneurs, engineers, and investors aiming to stay at the forefront of their respective fields.

Understanding 3D Printing and Its Role in Creating Wings

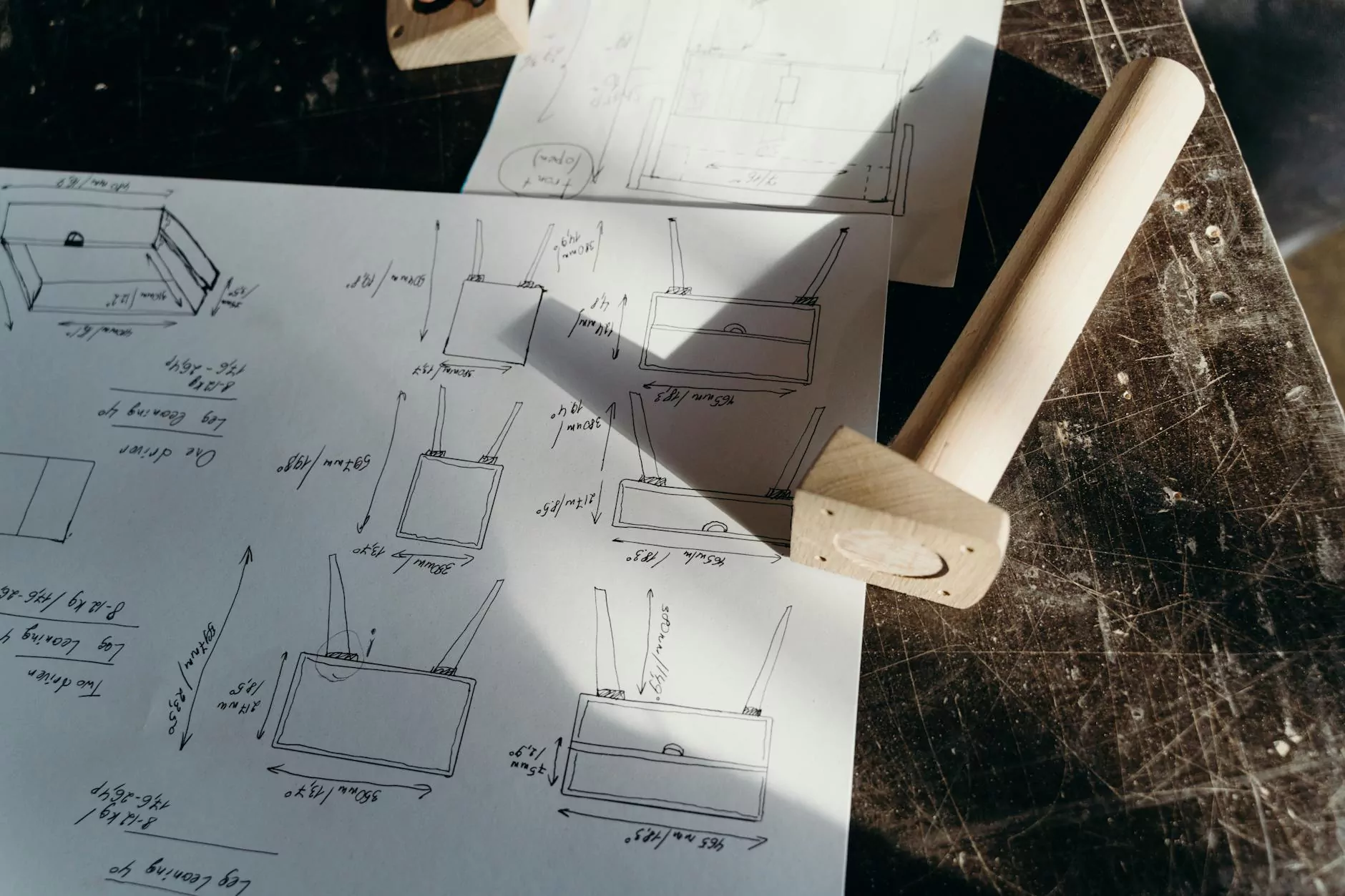

3D printing, also known as additive manufacturing, involves constructing three-dimensional objects by layering materials based on digital models. When applied to the creation of wings, this technique enables unprecedented flexibility in design, allowing for complex geometries that traditional manufacturing methods cannot achieve. The process involves several steps:

- Design Development: Using advanced CAD (Computer-Aided Design) software, engineers create detailed wing models that incorporate optimized aerodynamics, lightweight structures, and material variations.

- Material Selection: Modern 3D printing utilizes a wide range of materials—including high-strength plastics, composites, and even metals like titanium—each suited for specific performance requirements.

- Layer-by-Layer Printing: The digital designs are then realized through precise layering, resulting in highly detailed and durable 3D printed wings.

- Post-processing and Quality Control: Final steps include surface finishing, structural testing, and quality assurance to ensure optimal performance for real-world applications.

The Advantages of 3D Printed Wings for Business Innovation

Businesses across various sectors are recognizing the transformative potential of 3D printed wings. Here are some of the key benefits that make this technology a game-changer:

1. Enhanced Design Flexibility and Customization

Traditional manufacturing constrains designers due to tooling limitations and material restrictions. In contrast, 3D printed wings allow for intricate, customized designs tailored to specific performance needs. This capability leads to innovations such as biomimicry-inspired structures that mimic natural wing designs for improved aerodynamics.

2. Reduced Manufacturing Costs and Time

By eliminating the need for multiple tooling processes and enabling rapid prototyping, 3D printed wings significantly cut down production timelines and costs. Businesses can iterate designs faster, bringing products to market more swiftly and with less financial risk.

3. Lightweight and Efficient Structures

Using advanced materials and precision engineering, 3D printed wings are typically lighter yet stronger than traditionally manufactured options. This advantage is particularly crucial in aerospace, where reducing weight directly correlates with fuel efficiency and operational costs.

4. Innovation in Materials and Sustainability

The development of eco-friendly, recyclable, and durable materials for 3D printing supports sustainability goals. Companies committed to environmental responsibility can leverage 3D printed wings to produce environmentally conscious products without sacrificing performance.

Applications of 3D Printed Wings Across Industries

While initially associated with aerospace and aviation, 3D printed wings have broad application potential:

Aerospace and Aviation

The most prominent and impactful industry utilizing 3D printed wings is aerospace. Engineers are designing aircraft wings with complex geometries that maximize lift, reduce drag, and improve fuel efficiency. The ability to produce lightweight, high-strength wing components on-demand reduces costs and accelerates innovation timelines.

Automotive Engineering

Automakers are adopting 3D printed wings for aerodynamic components and structural elements. Customizable aerodynamic features serve performance and aesthetic purposes, resulting in vehicles that are both visually striking and functionally superior.

Fashion, Art, and Personal Accessories

The fashion industry is pushing the boundaries of accessories and wearable art with 3D printed wings. Designers create intricate, lightweight wings for costumes, jewelry, and avant-garde fashion, opening new avenues for creativity and uniqueness.

Military and Defense

In defense applications, 3D printed wings can be part of drone technology or special aircraft components. Rapid prototyping and on-site manufacturing facilitate quicker deployment and customization for mission-specific requirements.

Biomedical Engineering

Innovators are exploring 3D printed wings as part of prosthetic and biomechanical systems, creating bio-inspired structures that facilitate movement and integration with human biology.

Step-by-Step Process in Creating High-Performance 3D Printed Wings

Designing and manufacturing 3D printed wings involves meticulous planning and execution. Here's how leading companies approach this complex process:

1. Conceptual Design and Computational Simulation

Before physical printing, detailed digital models undergo simulation to analyze stress distribution, aerodynamic efficiency, and material performance. Advanced software like ANSYS or SolidWorks is used to refine wing profiles for maximum efficiency and durability.

2. Prototype Development and Testing

Using rapid prototyping, initial 3D printed wings are produced to evaluate form and function. Wind tunnel testing and finite element analysis are conducted to optimize design parameters, ensuring the final product meets all performance standards.

3. Material Optimization and Final Printing

Selection of optimal alloy or composite materials ensures strength without adding excess weight. The final 3D printed wings undergo post-processing steps, including surface smoothing, stress relief, and structural reinforcement.

4. Integration and Deployment

After passing rigorous testing phases, the wings are integrated into larger systems, such as aircraft or drones. Continuous feedback loops engine performance assessments and guide subsequent design improvements.

Future Trends and Innovations in 3D Printed Wings

The pursuit of innovation in 3D printed wings is ongoing, with emerging trends promising even greater capabilities:

- Bio-Inspired Wing Designs: Mimicking natural wings, such as bird or insect mechanics, to improve lift and maneuverability.

- Smart Wing Modules: Embedding sensors and actuators within wings for adaptive aerodynamics and real-time performance adjustments.

- Multi-Material Printing: Combining different materials within a single structure to optimize strength, flexibility, and weight.

- On-Demand Manufacturing: Deploying portable 3D printers for rapid, localized production in remote or hostile environments, improving operational efficiency.

Why Choosing the Right Partner Matters: The Role of 3Dprintwig.com

For businesses aiming to harness the full potential of 3D printed wings, selecting a reliable partner with expertise in 3D Printing is critical. 3dprintwig.com offers unmatched experience in designing, prototyping, and manufacturing custom wing components tailored to diverse industries. Their advanced technology, quality assurance, and dedication to innovation position them as a leader in this transformative field.

How to Leverage 3D Printed Wings for Your Business Growth

Integrating 3D printed wings into your product design and manufacturing process can unlock significant competitive advantages:

- Accelerate R&D: Reduce development cycles with rapid prototyping and iterative testing.

- Boost Innovation: Experiment with complex geometries and unconventional designs that push creative boundaries.

- Economize Production: Lower tooling and material costs while enabling on-demand manufacturing.

- Enhance Sustainability: Use eco-friendly materials and reduce waste through precise additive manufacturing.

- Stay Ahead of Competition: Adopt cutting-edge technologies that differentiate your offerings and attract modern consumers.

Conclusion: Embracing the Power of 3D Printed Wings for a Brighter Business Future

The realm of 3D printed wings exemplifies how technological innovation can revolutionize traditional industries, creating pathways for sustainable growth, exceptional design, and operational efficiency. As companies embrace this advanced manufacturing technique, they position themselves at the forefront of a new era where creativity knows no bounds, and productivity soars. Partnering with experts like 3dprintwig.com provides the expertise, quality, and innovation necessary to harness the full potential of this transformative technology.

In a world where agility, customization, and sustainability are paramount, leveraging 3D printed wings can truly set your business apart, fostering a future of limitless possibilities and exponential growth.